EME Unit 5 5.1 Concept of linear measurement and its instruments : surface plate, V – block, calipers,

Introduction:

Linear measurement is the measurement of Diameters, Lengths, Thickness, Heights

and also which are includes internal measurements and external measurements.

The basic principle of linear measurement is that of comparison with standard dimensions on a suitably engraved instrument or device.

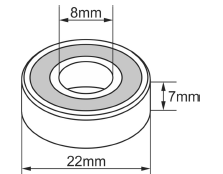

Example : Dimension of Bearing Outside diameter, Inside diameter, Thickness

The various devices used for measuring the linear measurements are

1. Vernier calipers 2. Micrometers

3. Slip gauge or gauge blocks 4. Comparators

1. Surface plate:

The surface plate is a massive solid structure, highly rigid in design which is having a true flatness of the surface.

Surface plate is a solid, flat plate used as the main horizontal Measuring Tools, plate used as the main horizontal reference plane for precision inspection, marking out and tooling setup. The surface plate is often used as the baseline for all measurements to the work piece.

In metrology, the Surface plate is used as a measuring base or a datum surface for testing of flatness of surfaces. Surface plate forms the basis of the measurement. Surface plates are widely used in where the inspection is carried out.

The surfaces plates are made up of Cast iron (C.I) and heat treated for relieving internal stresses. The top face of the surface plate is designed as truly flat. The back side of the surface plates is having ribs to increase the structural rigidity to withstand the heavy loads.

It is supported by leveling screws to make sure to adjust the surface plate to be truly horizontal.

Materials used to make Surface Plates :i) Cast Iron (C.I) ii) Granite iii) Glass

2. V Block :

V-Block is a jig structure which is having True V faces(Grooves) and slots. The main purpose of this V-block is to hold the Cylindrical objects in place for marking the centres for further lathe machining.

The angle between the V faces (Grooves) is 90° and 120° angled V-blocks are also available.

They can be available in different Grooved shapes.

To hold the workpiece in place, C/U-Clamps are provided with a Clamp Screw.

The U-clamp will engage with the V-block by the rectangular slots provided on the Side faces. As shown in the picture.

Magnetic V-blocks are also available so that there is no need for this U clamp.

There is a control button to control the magnetic forces. The magnetic force will hold the object after turning the knob to ON position.

Based on the accuracy in flatness these V-Blocks are classified into two grades

Grade-A and Grade-B.

Uses of V-Block :

1. Used to Hold the Cylindrical Objects in place for marking centerlines with the Surface gauge.

2. To hold down the rectangular job piece at 45° angle to the vertical direction.

3. Used as supports while holding long Cylindrical bars parallelly (They can be two of them or multiple V-Blocks based on the length of the cylindrical object.)

4. Can also be used to check the roundness of the cylindrical objects.

3. Calipers :

It is an instrument for measuring external or internal dimensions, having two hinged legs resembling a pair of compasses and in-turned or out-turned points.

They are measuring instruments having two usually adjustable arms, legs, or jaws used especially to measure diameter or thickness

Caliper has two legs same like compass and different types are used for each external and internal measurement. Extreme end of legs are the measuring points and called Tip.

Different type of tips is made to cope up various measurement types and to meet different measuring conditions. The legs are adjustable to open and close for a certain range in every caliper.

Types of Calipers:

There are many shapes and tip designs of caliper for different purposes but mainly four types:

Inside Caliper:

Its measuring tips are facing outward side and opposite to each other so used for internal measurements.

Outside Caliper:

Its measuring tips are facing inward side so used for external measurements as both tips are in same direction which in inward.

Divider Caliper:

It mostly used to transfer the same dimensions one place to another object or part and to draw the parallel lines, circles and divide objects into equal parts by marking through its scriber type tips

Comments

Post a Comment